- Use of sampling inspection for initial component Acceptance (Before Production).

- Use of Auto-CAD for 2D and PRO-E for 3D Modelling.

- Strict compliance to major and critical dimensions, as well as maintain a PDIR for every batch we machine.

- Use of check sheets and flow charts at every operation.100%SPC for all critical dimensions as specified by vendors.

- Dedicated inspection to check Dye Penetration Testing and Heat Treatment parameters.

- 8D & 5 Why analysis for all Production related non-conformances.

- Welding Penetration Testing done every scheduled date reaching the specific quantity.

- Use of Optical, Pneumatic, Mechanical comparators for measurement purpose used for quality assurance.

- FMEA for every component before production.

- PPAP (Part Product Approval Process) done for every component before production starts to meet the quality acceptance from every vendor.

- 100% conformance to gauge calibration plan and calibration certified by NABL accredited laboratory.

- Total Quality Management:- Use of 5S,kaizen,Poka Yoke, JIT, Zero Defects (Ongoing Techniques).

- Planning of resources materials and Inventory required.

- Use of Surface Tester (Make:- Mitutoyo) for checking surface finish.

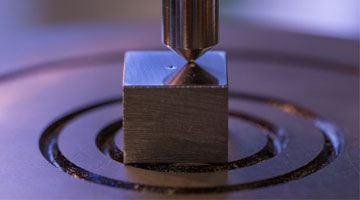

Metallurgical Testing

Micro hardness testing ,Infrared Radiation Thermometer, Hardness Tester(Brinell,Rockwell,Vicker) Dye Penetration Testing can be done for any particular component as per requirements.

Metrological Testing

CMM,Surface Finish Tester,Bevel Protector,Roundness Tester are available in-house/outdoor for testing critical dimensions as specified by the vendors.

QUALITY POLICY

We at KRB Engineering are committed to enhance customer satisfaction ,by meeting customer requirements beyond their expectations. To achieve this we shall implement the continual improvements and employee involvement at all level of organization.